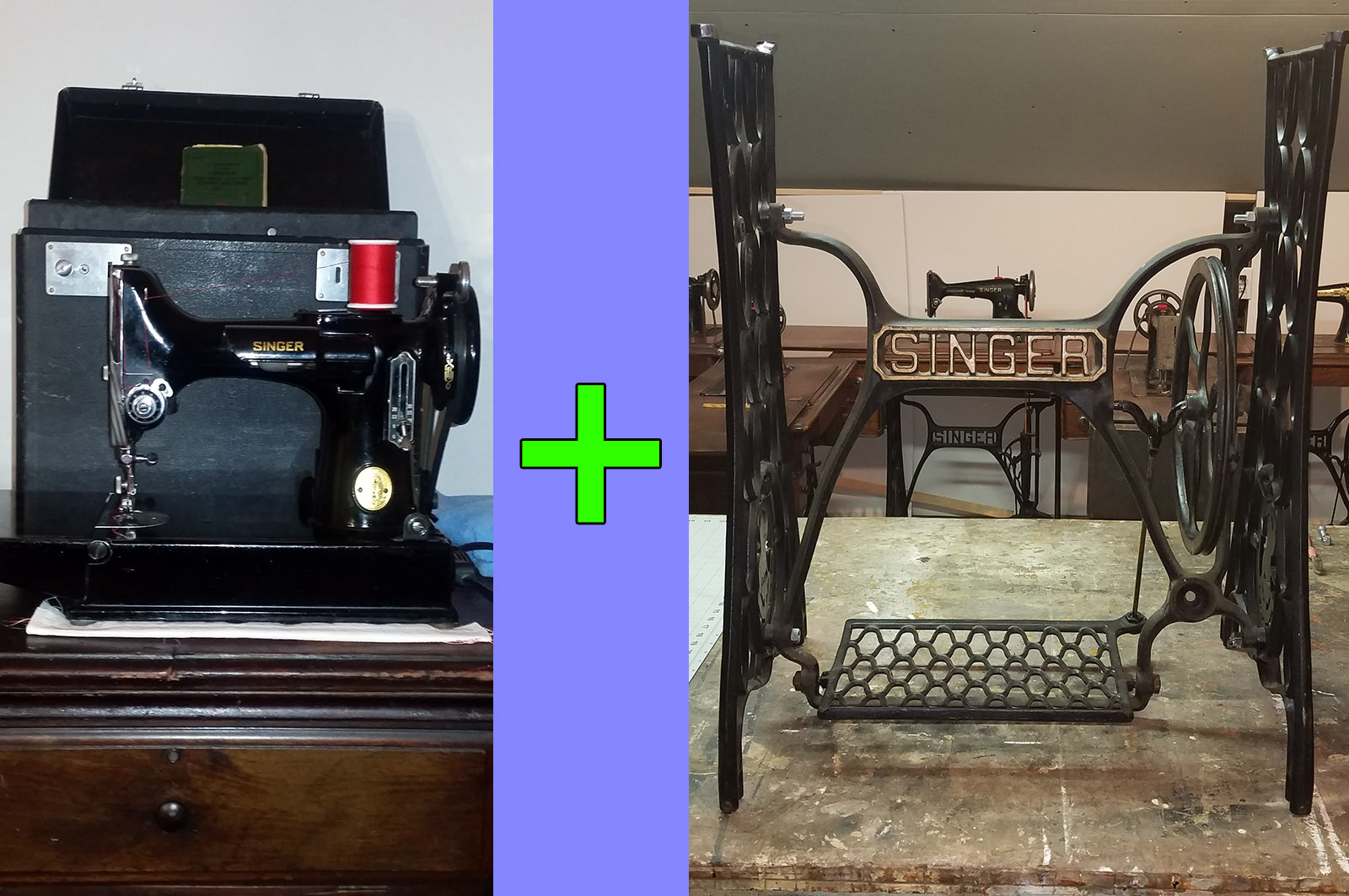

I've hinted around about planning this for years. Well I've finally gone and done it.

It's not a machine conversion, the 221 still has all its super-cute little parts attached. It's more of an adaptation to of a treadle to drive a 221.

First off, is it possible just to set a 221 on a treadle table and go after it? Sure. But the problem is that doing that means the treadle belt will rub against the finish and the plug and wear on them. I wanted something that would be a long term working setup that could be used for more than "look what I did" purposes.

I went through several plans on how to do it. I thought about using bushing and shims to line up a normal 9 spoke handwheel to overhang the edge of the machine. That's a lot of machining of parts that would have to be swapped to go from electric drive to treadle and back. I want the 221 to still be able to be quickly put in its case and carried off. So I nixed that.

My next idea was to do a magnetic couple with the motor's drive pulley. But as I mentioned to Cheryl in a reply to her comment in a previous post. There's a lot of inertia to overcome to get the motor to turn. That's energy that's wasted.

So my eventual plan came to a compound drive system. This first version is just a proof of concept, so I'm using scrap wood and cheap Chinese parts. If it goes well the next version will be quality 1950s cutting edge tech, like Lexan.

So here's my build process. I started by cutting 3 3.5" x 4.5" pieces of 3/4" plywood for to mount the pulley contraction on.

Then I had to do a cutout in one of the pieces so it could set over the motor.

A second piece had to be cut into a "U" shape so the pulleys and belts could be mounted.

Pilot holes drilled in everything so the wood wouldn't split when screwed together.

Everything was screwed together and the pulley contraption made out of some really cheap pillow bearings, 8mm shaft and timing pulleys were set on top to check and see that it would line up and clear the motor on the 221.

I'll call this Version 1. It was a mess. I have way too much going on with this thing for it to work right. The pulleys located inboard of the bearings mean that I have to disassemble it or the belts to take the table off the irons. The location of the balance wheel drive pulley is just never going to work well, even with a bicycle chain guide I was planning on using to get the belt below the belt guard. There's a lot more as well, but it did give me the ideas of how to streamline the configuration.

Behold Version 2.

Much simpler. Pulleys mounted on the outside of the bearings so the belts and be flipped on and off easily. Outside mounting also lets me get in the original belt path so no wonky guides needed. I also went with two 60 tooth timing wheels rather than trying to steal power buy doing the step-up. The smaller pulleys just can't hold the belt as well as the larger ones.

Also, originally I was using stockings as my belt (since I didn't want to chop up any of my nice stockpile of brand new leather, and yeah I have just as much 6mm for domestics as I do of the industrial thickness). It worked fine except its so slick that any hiccup and it would loose traction. So I ran down to the local pet store and bought some aquarium air tube. It works great. It's pretty stretchy, so that has to be taken into account when cutting it.

I was happy enough with it that I even did a video showing it in action.

And finally, it's all for naught if the stitches are crap. So here they are (I have no idea where those funky dark horizontal streaks came from on the photos).

Pretty much what I expected from a 221. Not the best, but better than what any modern machine or zig-zagger outside the 107W5 has given me. I think I'll call it a win and plan my next adaptation. I'm thinking a treadle 500A. Really. I already have the parts ordered to do it. It will be a bit more involved since it will be going with gears as well, to drive the shaft of a gutted PA motor.

But that's in the future. Here's one last glory shot of the 221 ready for the 1880s. (That leather belt wrapped around the brace is the 107W5's. I borrowed its treadle for this experiment.)

I was wondering if you could contact me as I do not see your email address anywhere. I have some question regarding your conversion. info@featherweightdoctor.com

ReplyDeleteSure, sent you an email.

DeleteCool! Too bad you can't be at my next demo to show that off.

ReplyDeleteKeep me posted on your demo schedules. I'll try to make one.

DeleteDavid...would a larger flywheel enable machine to work faster, i.e., more stitches per turn of wheel?

DeleteOff the 221 topic--does size matter in flywheels for treadling? Can you get more stitches per inch with a larger flywheel? If so, have you created a treadle setup with a larger flywheel?

ReplyDeleteYes, a larger flywheel will go faster. I have an industrial treadle with an 18" flywheel for the 103. The larger flywheels can be a pain to find though. Industrial machines tended to be converted to other drive mechanisms quicker than domestics and the flywheels taken off and tossed. They are more common in Europe.

Delete