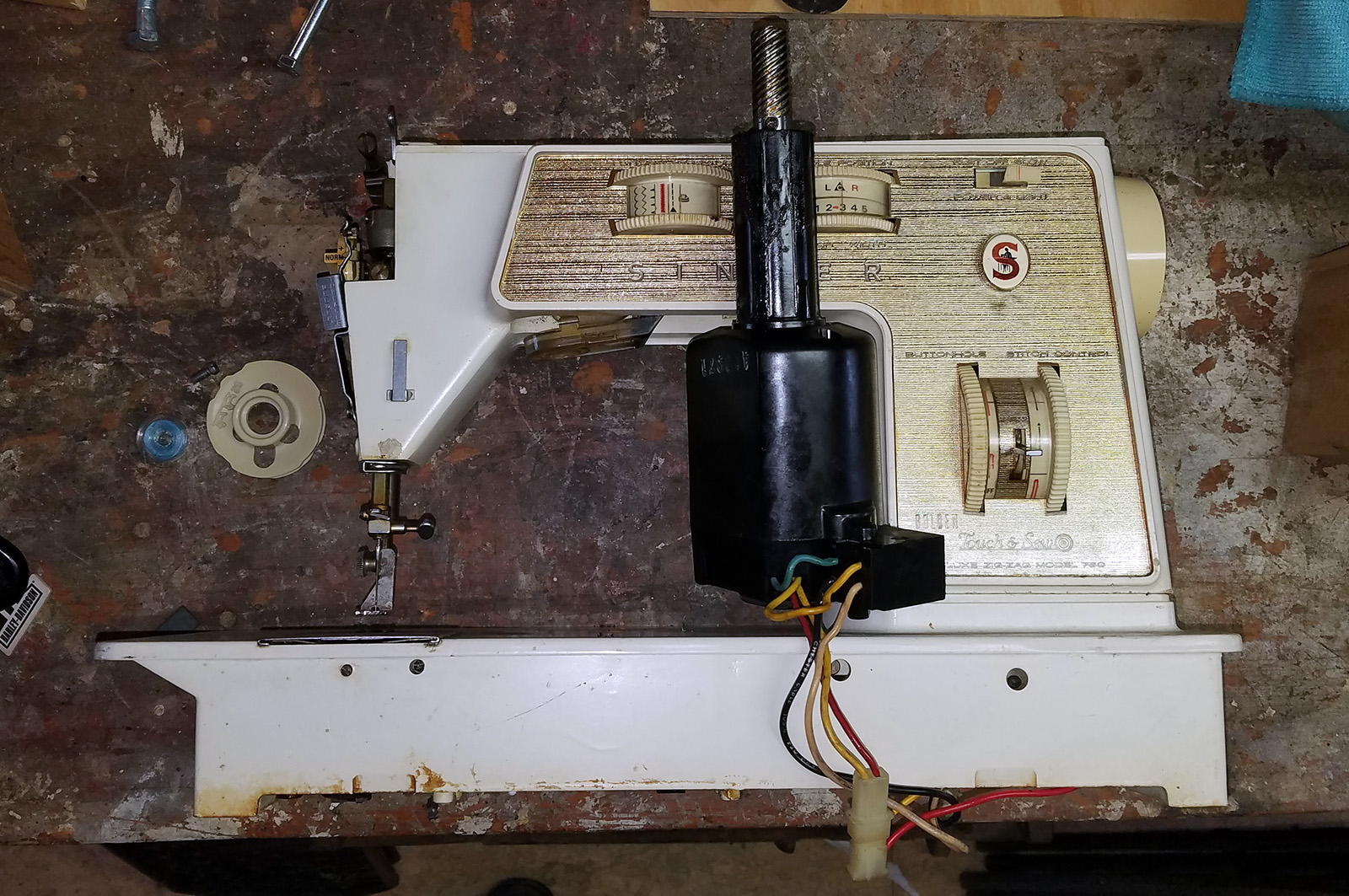

Well the 635 bombed out. I did get a good pedal out of it. And I guess a spare PA motor I can work on another project with. But every day is a new hope, right? I bought this off Shopgoodwill and it showed up today.

A Singer 750 Golden Touch and Sew. It appears that "Golden" matters for the motor conversion. The 635 wasn't Golden and had a plain motor. I dove right in and started ripping it apart.Let's start with the obvious. When your quality has sunk so low that your feel the need to put a "Quality Certification" on your plastic piece of junk. A - Don't do it on a peel and stick label. B - At least put it on straight. Sheesh! I guess they are certifying that it's crap quality. Well other than the motor. Yes! 1 amp.

This machine is late enough that people have quit caring about the serial numbers by this point. ISMACS peters out at AT032500 in May of 1971. I figure they probably made it to AT070000 by the end of the year. It doesn't matter that much, so yeah, I'll call it a '71 if anyone cares. The 70s suck is coming on hard at this point.

First thing to do was plug it in and check the motor. This time its just what I was looking for. After a quick spin I ripped the motor out.

To get the rest of the electrical out I needed to take the dash off, same as the 635. The screw holding it on is under one of the few cool things about the machine. The Singer logo button.

The plastic plate itself seems to be a bit lower quality than the 635's. Not a big surprise there. Pretty much everything other than the motor on this thing was a huge drop from poor quality of the 635.

Case in point, the light housing. Actually the 635's might have been just as crappy, I didn't even look at it. On the 750 it's molded from a single piece of plastic, half dyed black and turning yellow with age. That got yanked and tossed.

Once I had the motor and electrical out I could have just been done with the thing, but I told my son I would give him the carcasses of any dead aluminum machines to be melted down. I settled in for a bit of "gut the piece of junk". The more I took it apart the worse my opinion of these machines sank.

Pulling the cam stack off I wasn't surprise at all to see the plastic gears had been shredded.

I took a lot of photos documenting just how poorly this thing was made. All the plastic... and cheap springs holding parts together. The older models where machined with amazing tolerances. This one looks like it was machined "meh, close enough," and then springs were added to hold parts together. It was just depressing.

With the 635 I kept telling myself, "Well, maybe I could scavenge some metal gears and stuff to get it into better shape." With this thing I just wanted to be done shelling it. I won't torture everyone with all the ranting and photos of bad quality parts like I did with the 635. Here's what the pile of to be scrapped parts looked like when I finished.

And this is the pile of "that's cool, or maybe I can use that somewhere" parts.

I'll probably dig out most of the screws from the junk pile too. I kept the plastic gears just to mess with. I'll never use them for anything functional. The control panel plate I'm keeping just to document that I did have a 750 at some point. Maybe I'll have a plate collage on the wall or something.

I have two more Touch and Sews that might make it to me. A 620 and a 770. Originally I was kind of excited about the 770, it's a Touch and Sew II with the free arm. I had been thinking that I might try giving it some metal gears and have a decent free arm Singer. But seeing how bad the quality dropped from the 635 to the 750 I'm now kind of hoping that I don't get it. I can only imagine how much of a piece of junk it is.

I probably won't get the motor conversion for a 4xx done before I leave for Philmont in a few weeks. I'll save that for a fall project. If the 620 and 770 arrive before I depart I might just stick them in a corner to get parted out at a later date as well. The Touch and Sews are just too annoying to work on at this point. I need to get back to working on quality machines.

I've avoided the Touch & Swears because of all the awful press they get on the sewing machine sites. Have fun at Philmont. Are you working the whole summer there?

ReplyDeleteThat was the original plan, but the boy has some academic issues that require him to stay home for the summer, so I'm just going to help them get set up for the season then come back. Maybe next year we'll all get to work out there.

Delete